TDS-400 Transport Drainage System

Network Rail Product Accepted (PADS)

Award Winners of The PWI

Climate Change and Decarbonisation Prize 2022

Network Rail

Network Rail

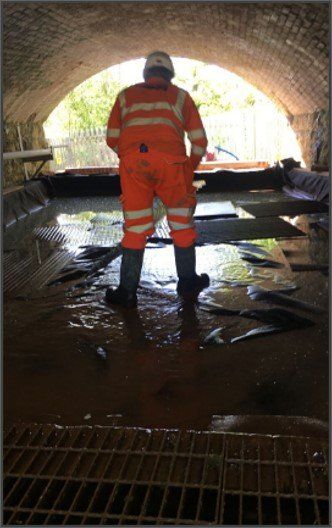

Trackside Drainage Interfaces

TDS-400 drainage panels are interfaced between the outflow of the track ballast, catch pits and existing track drainage assets. The drainage panels immediately increase the flow-rate and reliable transmission of water away from the track bed.

With an estimated install rate of over 60 meters per hour, there are significant cost savings compared to traditional methods used to remediate trackside drainage - typically as little as only 2.5 meters per hour.

Download: Trackside Drainage Engineering Drawings

TDS-400 Track Deployment

1.

All contaminated ballast and other materials in the 6ft interval or affected areas are removed.

2.

All arising’s are removed from site and disposed of at an EA licensed disposal site or used as yard spread where appropriate.

3.

High pressure water jetting is undertaken of the existing track drainage system and or 6ft track drainage system.

4.

A CCTV survey produces a summary report for the existing track drainage system and or 6ft track drainage system.

5.

An RRV with excavator pulls back the ballast next to the existing track drainage system and TDS-400 drainage panels are installed.

6.

Depending on drainage run length and site conditions a second RRV with excavator will increase installation speed by back filling after installation, while the first RRV and installation team continue ahead.

The conveyance of water into track drainage assets, catch pits, existing pipes, between the pipe protection and the Down Main 6ft rail is immediately increased.

Installation Guidance

> Install alongside, above and between track drainage assets such as catch pits, existing drainage lines or the toe of cutting slopes. The open void structure enables excess water and fine silts to be rapidly taken away from the track ballast or toe of the cut, and into existing track drainage systems.

> Install TDS-400 drainage spurs at 3-5 meter intervals within the track ballast.

> Install no more than 150mm into the shoulder.

> Remediate more serious/acute drainage problems by adopting a reduced distance between TDS-400 drainage spurs and by overlapping multiple drainage panels side by side. Target the worst affected areas.

Swipe left on table

| Installation Rate | Cost Per Meter | Project Shifts | Installation Cost | Cost Saving | |

|---|---|---|---|---|---|

| TDS-400 | 60 meters per hour | £120 | 1300m 14 shifts | £2.3m | £2.5m |

| Traditional | 2.5 meters per hour | £340 | 1300m 66 shifts | £4.8m | N/A |

Above typical savings calculated by a rail supervisor during live trials within the UK rail network. Traditional trackside remediation works using Road Rail Vehicle (RRV) 1 x Operator, Labour & Safety Control Staff, Road Railer 2 x Trailers and 1 x Box and normal 6m drainage lengths. Output based on an 8hr working shift and is dependent on access restraints, possessions, isolations and general site conditions.

Modular Silt Control Barriers

TDS-400 modular silt control barriers protect against storm surges and reduce the frequency of site maintenance visits to replace fouled silt traps and Geotextile linings in the settlement tank.

Installed directly on site, in less than a day.

Civil Grade Drainage Systems

Drainage Specification Appraisals Available On Request

Location

Civil Water Management Ltd

Unit 9 Offices, Leeds Bradford Airport Industrial Estate

Harrogate Road, Yeadon

Leeds

LS19 7WP

Email

carl@civilwatermanagement.comManaging Director

TDS-400

Transport Drainage System 400:

Advanced drainage systems for Rail, Highways, Civil Engineering and Government Agencies.

Menu

Contact Our Specialist Team

- Mon - Sun

- Open 24 Hours

UK Certified Manufacture

• ISO 9001 Quality Standard (site)

• ISO 14001 Environmental Standard (site)

• OHSAS 18001 Occupational H&S Standard (site)

© 2024

All Rights Reserved | Civil Water Management Ltd